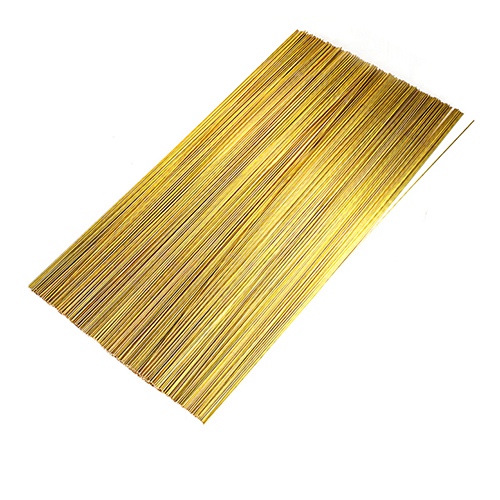

Brass Brazing Copper Pipe Welding Rod is specialized welding materials designed for stick welding processes, particularly for joining brass and other metals. The stick welding format enhances convenience and ease of use during welding operations. Copper-phosphorus solder is a solder based on copper and zinc alloy. It has good fluidity and is suitable for contact brazing, flame brazing, high-frequency brazing and furnace brazing. It improves the wetting ability of the solder. , improve strength and toughness, and lower melting point. Copper-zinc solder is mainly used for flame, high-frequency, resistance and other brazing methods.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | Zn | Sn | Si | Other | F | ℃ | F | ℃ | |||

| BCu | BCu-1 | / | 100 | / | / | / | / | 1981 | 1082 | 1981 | 1082 | Suitable for furnace brazing of steel, stainless steel and nickel-based alloys. |

| BCu58Zn | / | / | 58 | / | 38 | / | Mn:4 | 1616 | 880 | 1668 | 909 | Mainly used for brazing of hard alloy cutter. |

| BCu60Zn | / | / | 60 | / | 39 | 1 | Si:0.25 | 1634 | 890 | 1661 | 905 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu58ZnFe | BCuZn-C | / | 58 | / | 40.2 | 1 | Fe:0.8 | 1670 | 910 | 1749 | 954 | |

| BCu48ZnNi | BCuZn-D | / | 48 | / | 41.8 | / | Ni:1 Si:0.2 | 1720 | 938 | 1799 | 982 | |

Brass stick rod electrode, commonly used for welding applications, possesses distinctive features and advantages that contribute to its popularity. Here are the key characteristics highlighted:

1. High Thermal Conductivity: Brass Brazing Copper Pipe Welding Rods are known for their high thermal conductivity, facilitating efficient heat transfer during the welding process.

2. Corrosion Resistance: Brass inherently exhibits corrosion resistance, ensuring durability and longevity in welded joints, especially in applications exposed to environmental elements.

3. Excellent Ductility: The rods maintain excellent ductility, allowing for flexibility in welding joints and reducing the risk of cracking or brittleness.

4. Versatility in Applications: Brass welding rods are versatile and suitable for welding a variety of materials, providing adaptability across different welding projects.

5. Aesthetic Finish: The welding rods yield an aesthetically pleasing finish, making them suitable for applications where visual appearance is important, such as decorative welding.

6. Low Fuming: Brass welding rods typically produce low fumes during the welding process, contributing to a safer and more comfortable working environment.

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

A Brass Brazing Copper Pipe Welding Rod is a type of filler metal used in stick welding (shielded metal arc welding) to join metals. It consists of a core wire made of brass, which is a combination of copper and zinc.

Brass Brazing Copper Pipe Welding Rods offer good electrical conductivity, corrosion resistance, and ductility. The specific properties can vary based on the composition of the alloy.

In stick welding, the brass welding rod is manually fed into the welding arc, where it melts and forms a molten pool. This pool solidifies to create a strong joint between the base metals being welded.

Brass Brazing Copper Pipe Welding Rods are commonly used for welding non-ferrous metals such as copper and brass. They may also be used for joining dissimilar metals in certain applications.

These rods find applications in various industries, including plumbing, metal fabrication, and art projects. They are often used for decorative welding due to the attractive appearance of brass.

As with any welding process, safety precautions are crucial. This includes wearing protective gear such as gloves and a welding helmet. Adequate ventilation is also important, especially when welding brass, to prevent exposure to fumes.

Brass is generally not recommended for structural welding due to its lower strength compared to steel. It is more suitable for decorative or non-load-bearing applications.