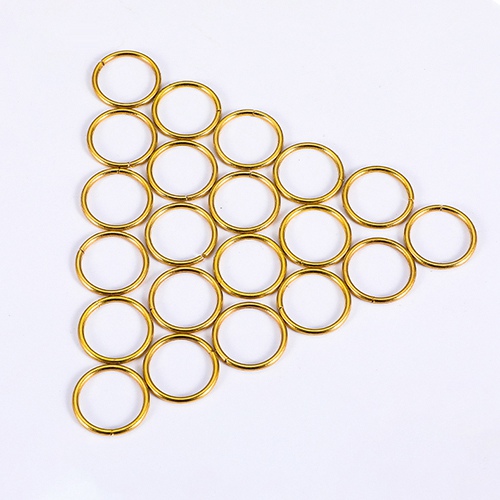

Guangdong Guangyanlong Welding Materials Co., Ltd, a top-rated Chinese manufacturer of brass brazing rings, is dedicated to producing top quality brazing rings for use in industrial applications. Illustrated above is our Brass Welding Ring for Electrical Applications, that has been intricately designed to provide dependable and efficient electrical connections. They are vital components in the overall brazing process which help to make sure that the joints in electrical hardware such as transformers and electric switches remain conductive, durable and strong.

These rings we manufacture using high grade brass with excellent thermal and electrical conductivity are essential for maintaining effective and safe electrical systems. The resistance to corrosion of these rings also exceeds those of others hence making them last longer even under difficult conditions. Given this scenario, at Guangyanlong we follow strict standards on product quality control backed by strong research and development capabilities with a view to meeting international specifications. Our dedication towards continuous improvement through customer satisfaction leads to better performing brass brazing rings that enhance your electric system’s strength while increasing the long-term dependability of your products.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | Zn | Sn | Si | Other | F | ℃ | F | ℃ | |||

| BCu | BCu-1 | / | 100 | / | / | / | / | 1981 | 1082 | 1981 | 1082 | Suitable for furnace brazing of steel, stainless steel and nickel-based alloys |

| BCu58Zn | / | / | 58 | / | 38 | / | Mn:4 | 1616 | 880 | 1668 | 909 | Mainly used for brazing of hard alloy cutter |

| BCu60Zn | / | / | 60 | / | 39 | 1 | Si:0.25 | 1634 | 890 | 1661 | 905 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu58ZnFe | BCuZn-C | / | 58 | / | 40.2 | 1 | Fe:0.8 | 1670 | 910 | 1749 | 954 | |

| BCu48ZnNi | BCuZn-D | / | 48 | / | 41.8 | / | Ni:1 Si:0.2 | 1720 | 938 | 1799 | 982 | |

Strong and Durable Joints: Brass Braze Rings ensure that joints are made strong such that they cannot be easily broken by mechanical stress or pressure caused on them. This durability is important where connections must be reliable and long-lasting such as in plumbing, HVAC, and electrical systems.

Ease of Application: These rings are meant to facilitate a smooth brazing process by enabling consistent uniform application. Consequently, this yields top-rate joints with little effort thereby minimizing installation mistakes.

Versatility: Brass Braze Rings can be used with various metals that include copper, brass, stainless steel among others ferrous and non-ferrous materials. Hence, it is possible for these kinds of rings to serve many industrial applications of different types.

Cost-Effective: Brass is an inexpensive material which strikes a balance between performance and cost. In this case choosing to use Brass Brazing Rings could lead to reduced overall costs on the project while still giving strong durable outcomes.

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Yes, Guangdong Guangyanlong Welding Materials Co., Ltd offers customization options for Brass Brazing Rings, including different sizes and compositions to meet specific customer requirements.

Joints made with Brass Brazing Rings are highly durable and can last for decades, depending on the environment and the application. They are designed to withstand mechanical stress and environmental factors.

Yes, Brass Brazing Rings are excellent for electrical applications due to their high electrical conductivity, ensuring reliable and efficient connections in electrical systems.

Use appropriate protective gear, work in a well-ventilated area, and follow all safety guidelines provided by the manufacturer to avoid exposure to fumes and high temperatures.

Yes, Brass Brazing Rings are commonly used in plumbing applications due to their corrosion resistance and ability to form strong, leak-proof joints in water systems.

Brass Brazing Rings perform well in corrosive environments, making them ideal for plumbing, marine, and outdoor applications where exposure to moisture and chemicals is common.esigned to provide dependable and efficient electrical connections. They are vital components in the overall brazing process which help to make sure that the joints in electrical hardware such as transformers and electric switches remain conductive, durable and strong.