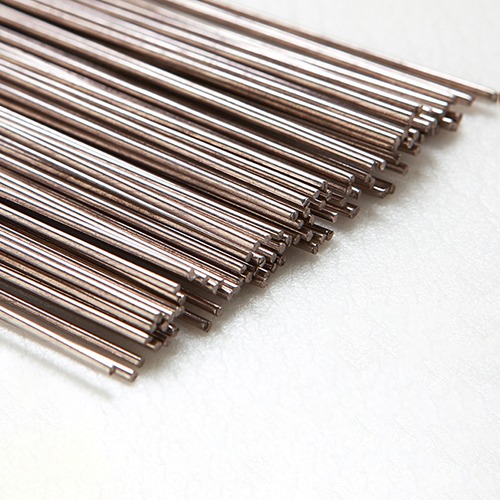

High Strength Silver Brazing Rod is the best and most reliable product there is for creating very strong joints in different metalworking processes. They are made as seen in photographs with a lot of silver content in them to ensure they have high mechanical strength and excellent conductivity. This makes it suitable for use by both professional and amateur metal workers.

They are preferred because they are manufactured by well-known Chinese 45% Silver Solder Suppliers. The high content of silver, typically around 45%, means that these rods have lower melting points, making brazing easier and faster as well. Their good liquidity allows the melted metals to flow smoothly into the joints without any gaps and produce uniform joint with better resistance to stress and corrosion.

These types of products can be used on various base metals such as copper, brass nickel or stainless steel among others; they are however ideal for plumbing works, HVAC systems, electrical connections, car repairs services among other applications such as jewelry production. When choosing this kind of product one should be aware that its bright shiny surface not only guarantees strong hard wearing joints but also adds an aesthetic appeal to the end product.

When you choose the above mentioned China 45 percent silver solder Suppliers what you get is a dependable source that delivers nothing less than quality goods which satisfy all required standards. These suppliers employ rigorous quality control procedures thus ensuring uniformity and dependability throughout all their supplies.

In summary, High Strength Silver Brazing Rod is essential when it comes to achieving quality brazed joints in many applications. It has superior properties of material together with manufacturing accuracy from top Chinese companies hence people would rather go for such items when looking for excellence on brazing works.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Less Oxidation while Soldering

During the process of soldering, this kind of solder produces minimal amounts of oxidation thus doing away with the need to have an extensive post-soldering cleaning to be conducted which in turn helps to maintain its aesthetic and structural integrity.

Better Mechanical Properties

For example, when 45 percent silver solder is used as a joint material, mechanical properties such as tensile strength and fatigue resistance can be enhanced; it also makes joint more durable and able to withstand mechanical stress.

Broad Range Application

The use of 45% silver solder is versatile in diverse areas such as plumbing systems, HVAC systems, automotive parts for vehicles’ electrical connections and aerospace components, jewelry making industries industrial machinery among others due to its adaptability and dependability that suits various industries.

Environmental Benefits

Silver is a recyclable substance hence 45 percent silver solder qualifies as environmentally friendly silver was used in making 45% silver solder. This reduces waste by enabling reuse of the product thus promoting sustainable manufacturing practices.

Uniformity and Dependability

This solder guarantees consistent quality and performance when obtained from genuine China 45 Percent Silver Solder Suppliers. For instance, Chinese manufacturers are known for adhering to strict quality control regulations that guarantee high standards within every production batch.

Compatible with Automation Techniques

It can be easily integrated into automated soldering machines thereby enhancing consistency during production of the consumer goods besides improving efficiency as well making it suitable for high-volume manufacturing environments.

Inexpensive

Despite having superior performance characteristics, it is possible for 45% silver solders to be cheap because they last longer, producing high-quality joints that can lead to lower maintenance costs on top of low repair rates over time.

Increased Fluidity

However, presence of silver in this alloy enhances its flow ability since molten metal flows with ease hence filling gaps between surfaces made of metals. It makes the bond between the parts more uniform and complete, and thus reduces chances of weak spots in the joint.

Yes, using an appropriate flux is recommended when soldering with 45 percent silver solder to clean the metal surfaces and promote the flow of the molten metal, ensuring a strong and reliable bond.

Yes, they can withstand high temperatures, making them suitable for applications involving significant thermal loads.

Yes, their high electrical conductivity makes them ideal for electrical and electronic applications, ensuring reliable connections.

Yes, provided the alloy composition is safe for contact with food.

Yes, they are versatile and can join both ferrous and non-ferrous metals.

Yes, they may need to meet specific industry standards, such as AWS (American Welding Society) or ISO (International Organization for Standardization) standards.