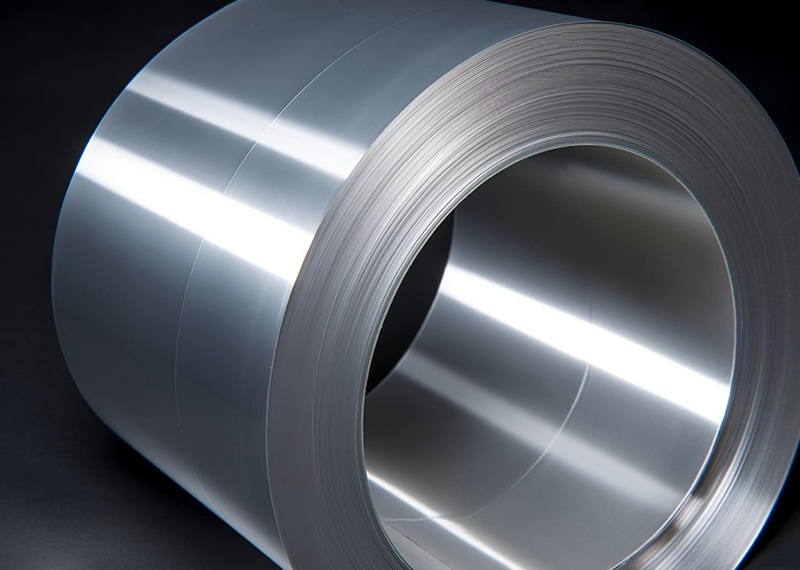

silver composite solder is a remarkable and versatile soldering material that has found a variety of applications across numerous industries. It combines the excellent properties of silver with other elements, creating a unique alloy with outstanding electrical conductivity, thermal conductivity, and corrosion resistance. In this article, we will delve into the world of silver composite solder, its composition, characteristics, and the diverse roles it plays in different sectors.

Composition and Structure:

Silver composite solder is essentially an alloy that incorporates silver (Ag) as a primary component, combined with one or more other metals or elements. The specific composition of silver composite solder can vary, depending on the desired properties for a given application. Common alloying elements include copper (Cu), tin (Sn), and sometimes other metals like bismuth (Bi).

High Electrical Conductivity:

One of the standout features of silver composite solder is its exceptional electrical conductivity. This property makes it a popular choice in the electrical and electronics industry. It is used to create connections in electrical components, circuit boards, and other electronic devices, ensuring efficient conduction of electricity.

Thermal Conductivity:

Silver composite solder also boasts excellent thermal conductivity. It is utilized in applications where effective heat dissipation is crucial. This property ensures that heat generated in electronic components can be efficiently transferred away, preventing overheating and damage.

Corrosion Resistance:

Many formulations of silver composite solder offer impressive resistance to corrosion. This characteristic is invaluable in applications exposed to various environmental conditions, ensuring long-term reliability. Corrosion resistance is particularly important in electronic devices and outdoor equipment.

Variety of Formulations:

Silver composite solder is available in various formulations, each tailored for specific applications. These formulations may have different percentages of silver and alloying elements to meet the requirements of specific industries and use cases. For example, silver-copper-tin alloys are common in electronics, while silver-bismuth alloys are utilized in low-temperature soldering applications.

Applications Across Industries:

The versatility of silver composite solder is evident in its widespread applications:

1. Electrical and Electronics: It is used in the manufacturing of printed circuit boards, semiconductor devices, and electrical connectors, ensuring reliable electrical connections.

2. Power Electronics: Silver composite solder plays a crucial role in power electronic devices, where efficient heat dissipation and electrical conduction are vital.

3. Automotive: It is used for soldering in automotive components, such as sensors, connectors, and control modules.

4. Renewable Energy: In the renewable energy sector, silver composite solder is employed in the production of solar panels and wind turbine components.

5. Medical Devices: It is used in the assembly of medical equipment, such as sensors and diagnostic devices.

Silver composite solder, with its excellent electrical and thermal conductivity, resistance to corrosion, and adaptability in various formulations, is an essential material underpinning many technological advancements. Its role spans from powering our electronic devices to enhancing the reliability of renewable energy systems and supporting the medical and automotive industries. As technology continues to advance and industries evolve, the versatility and reliability of silver composite solder ensure its enduring importance in modern manufacturing and technology.