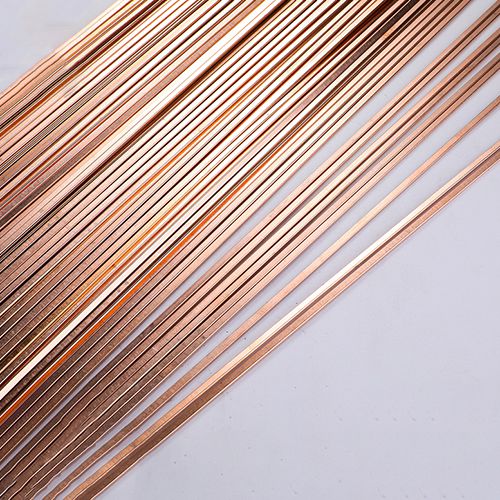

Copper-phosphorus alloy electrode is specialized electrodes used in different welding and brazing operations. Usually, they are made from copper alloys which have specified quantities of phosphorus. The amount of phosphorus in the alloy is important for improving the welding or brazing process. Phosphorous-copper solder is a solder based on binary alloy copper-phosphorous. It has good fluidity and is appropriate for contact brazing, flame-brazin g, high-frequency brazing and furnace-brazing. Incorporating silver into the phos-copper alloy will improve the solder wettability tremendously, enhance its strength and toughness while lowering its melting point thereby making it ideal for use in refrigeration industry as well as, motor, electrical appliance, instrument among other production industries. Copper-zinc solder is primarily applied to such joining techniques as flame-, high-frequency-, resistance- brazings etc. To learn more about these materials and their applications consult China Copper–Phosphorus Alloy Electrode Manufacturer.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | P | Zn | Sn | Other | F | ℃ | F | ℃ | |||

| BCu93P | BCuP-2 | / | 93 | 7 | / | / | / | 1310 | 710 | 1460 | 795 | Suitable for copper and copper alloy,with good fluidity. |

| BCu86P | / | / | 86 | 7 | / | 7 | / | 1134 | 657 | 1270 | 687 | Mainly used for brazing of hard alloy cutter |

| BCu91PAg | BCuP-6 | 2 | 91 | 7 | / | / | / | 1190 | 645 | 1450 | 785 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu89PAg | BCuP-3 | 5 | 89 | 6 | / | / | / | 1190 | 645 | 1325 | 720 | |

| BCu88PAg | BCuP-4 | 6 | 86.7 | 7.3 | / | / | / | 1190 | 645 | 1275 | 690 | |

| BCu80PAg | BCuP-5 | 15 | 80 | 5 | / | / | / | 1190 | 645 | 1300 | 705 | |

| BCu75PAg | BCuP-6 | 18 | 75.5 | 6.5 | / | / | / | 1190 | 645 | 1190 | 645 | |

Enhanced Flow: For increased smoothness and evenness of welding and brazing.

Lowered Melting Point: Less energy-intensive.

Improved Wetting Ability: A sturdier, more trustable bond.

Improved Strength and Toughness: Long-lasting, tough welds

Versatility: Applicable to contact, flame, high frequency and furnace brazing techniques among other things.

Corrosion Resistance: It has good resistance against extreme conditions.

Cost-Effectiveness: Cheap as compared to costly alloy electrodes.

Phosphorus copper solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in the refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Phosphorus improves flow and wettability, lowers melting point, and acts as a deoxidizer, reducing the need for additional flux during brazing.

Yes, adding silver to copper phosphorus alloys improves wettability, strength, and toughness, and further lowers the melting point.

These electrodes are widely used in the refrigeration industry, motor manufacturing, electrical appliances, instrumentation, and various other manufacturing industries.

Copper phosphorus alloy electrodes are suitable for contact brazing, flame brazing, high frequency brazing, and furnace brazing.

They are generally more cost-effective than pure silver or other high-cost alloy electrodes, achieving a balance between performance and cost.

The phosphorus content acts as a deoxidizer, thereby reducing the need for additional flux during brazing, simplifying procedures and reducing costs.