Phosphor copper brazing alloy is a unique material that consists of both copper and phosphorus for use in braze welding. Phosphor copper solder consists of two elements –copper and phosphorus. This mixture of metals makes it possible to deoxidize the joint, as phosphorus does not allow oxide formation at the time of brazing. It has good flowability properties, making it suitable for dip-brazing, torch brazing, high-frequency and vacuum furnace brazing purposes. Additionally, the addition of silver remarkably enhances its wetting ability, while increasing its strength and toughness and lowering its melting temperature even further. It has a wide range application in refrigeration industry besides motor manufacturing, electrical appliance industry or instrument manufacturing among others used primarily for flame brazing (high-frequency induction heating), resistance brazing etc regarding this type of material; one can also consult china phosphorus copper manufacturers.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | P | Zn | Sn | Other | F | ℃ | F | ℃ | |||

| BCu93P | BCuP-2 | / | 93 | 7 | / | / | / | 1310 | 710 | 1460 | 795 | Suitable for copper and copper alloy,with good fluidity. |

| BCu86P | / | / | 86 | 7 | / | 7 | / | 1134 | 657 | 1270 | 687 | Mainly used for brazing of hard alloy cutter |

| BCu91PAg | BCuP-6 | 2 | 91 | 7 | / | / | / | 1190 | 645 | 1450 | 785 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu89PAg | BCuP-3 | 5 | 89 | 6 | / | / | / | 1190 | 645 | 1325 | 720 | |

| BCu88PAg | BCuP-4 | 6 | 86.7 | 7.3 | / | / | / | 1190 | 645 | 1275 | 690 | |

| BCu80PAg | BCuP-5 | 15 | 80 | 5 | / | / | / | 1190 | 645 | 1300 | 705 | |

| BCu75PAg | BCuP-6 | 18 | 75.5 | 6.5 | / | / | / | 1190 | 645 | 1190 | 645 | |

1. Phosphorus Content: Phosphorous is an integral part of phos-copper brazing alloy, It imparts fluidity to this alloy enabling it to bond effectively with the surfaces being joined.

2. Low Melting Point: Typically, the alloy has a low melting point hence there is efficient brazing without subjecting the base materials to extremely high temperatures.

3. High Fluidity: When molten, Phos-Copper alloy has very good flowability thereby ensuring a strong and reliable bond by allowing easy and even distribution between connected surfaces.

4. Capillary Action: It shows capillary attraction; therefore it can penetrate minute openings and narrow spaces appearing between mating surfaces facilitating close fitting bonds.

5. Corrosion Resistance: The latter offers corrosion resistance that ensures longevity and durability.

6.Good Thermal Conductivity: During the process of brazing, the metal maintains its capacity to transfer heat efficiently.

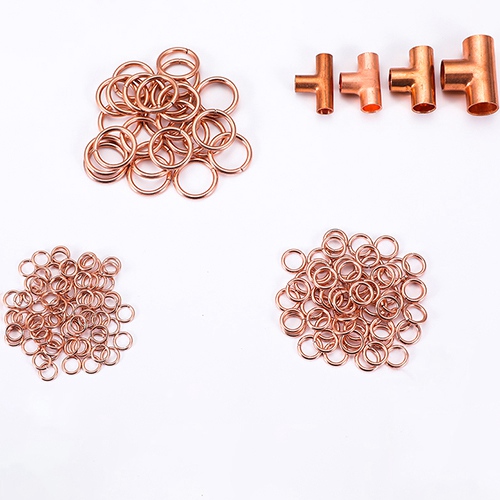

Solder made from phosphorus copper is typically used in regular flame welding among other applications Its use mainly takes place in refrigeration, air conditioning, plumbing and electrical industries. We are able to produce any kind of formulas and can also work with R&D and customization to cut costs down thereby increasing efficiency on your production. When you need more information about this issue, please contact your technical department.

Phos-Copper Brazing Alloy is a type of brazing filler metal composed of copper alloyed with phosphorus. It is designed for brazing applications where strong and durable joints are required.

Phos-Copper Brazing Alloy possesses high fluidity, good wetting ability, and excellent capillary action. These properties contribute to its effectiveness in creating strong joints during the brazing process.

This brazing alloy is commonly used in HVAC (heating, ventilation, and air conditioning) systems, refrigeration, plumbing, and various metalworking applications. It is suitable for joining copper and copper alloys.

The addition of phosphorus improves the alloy's ability to flow and wet the base metals, ensuring a reliable bond. It also contributes to the alloy's resistance to corrosion.

While it is primarily designed for brazing copper and copper alloys, Phos-Copper Brazing Alloy can also be used for brazing other metals like brass and bronze, depending on the specific requirements of the application.

In most cases, post-brazing cleaning is not necessary for joints made with Phos-Copper Brazing Alloy. The alloy produces clean and aesthetically pleasing joints.

Standard safety precautions for brazing should be followed, including the use of appropriate personal protective equipment and ensuring proper ventilation in the workspace.

Yes, joints made with Phos-Copper Brazing Alloy can withstand relatively high temperatures, making them suitable for applications in which the brazed joints may be exposed to elevated temperatures.

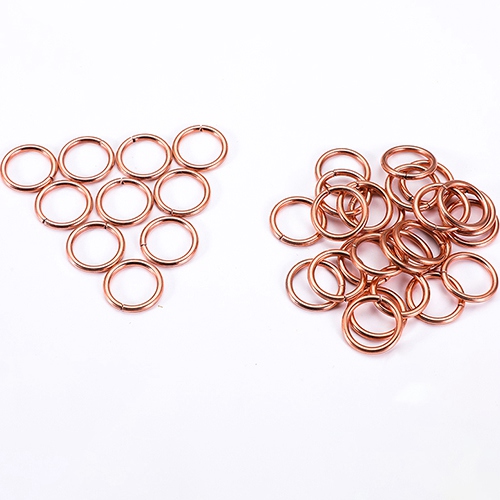

Phos-Copper Brazing Alloy is available through welding and brazing supply stores, as well as specialized metal suppliers. It is often sold in the form of rods or wire for ease of use.