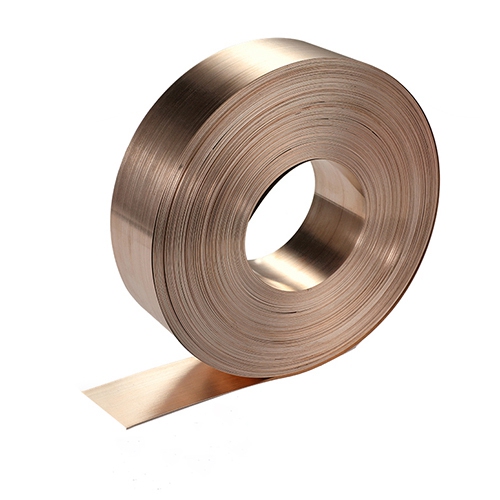

The Silver Solder for Jewelry is a valuable product specially made for jewelry makers and metalworkers. It comes in strip form, as can be seen on these pictures, hence easily handled and accurately applied. Due to its high silver content, it exhibits excellent conductivity and strong bonding making it ideal for creating fine jewels.

This kind of silver solder stands out from other brands produced by the leading China High silver welding strip Suppliers due to their quality and performance superiority. The soldering process becomes easier and faster with the lower melting point obtained through accurate alloy composition. In addition, the alloy has good fluidity that allows it to spread into joints. This way, the joints become filled up eliminating voids or spaces between surfaces that often lead to stress cracks or corroded parts.

Additionally, this may be used in jewelry making ranging from delicate repairs to the crafting of intricate designs. With its high silver content, you are guaranteed of strong joints which also enhance the beauty of your final piece due to bright finishes. Furthermore when working on rings (bracelets; necklaces; custom pieces), this kind of silver solder ensures that your work will last for a lifetime while maintaining its elegance.

To get such product, one should consider purchasing silver solders from reliable China high silver welding strip Suppliers whose artisans only make products that are unconditionally accepted both at national and international levels as they strictly comply with all rules & regulations pertaining product quality management system.

In brief, The Silver Solder for Jewelry is designed in such a way so as enables people who use it achieve high standard metallic binding whenever they apply it on different types of ornaments. As a result of this material’s superior properties coupled with strictness of manufacturing based on Chinese top suppliers’ norms one can surely expect perfect output if some metalwork activity is under consideration.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Welding with minimized oxidation

These welding strips have an effective minimal oxidation during the process of Welding in order to avoid excessive cleaning required after-welding and to retain beautiful appearance as well as strength of welded joint.

Better Mechanical Properties

High silver welding strips may optimize the mechanical properties of the joint, which include tensile strength and fatigue resistance. They make such unions more resistant to wear and tear due to physical forces applied on them.

A Wide Variety of Applications

This means that high silver welding strips can be used in various sectors like electronics, electrical connections, plumbing, HVAC systems, automotive, aerospace, industrial machinery and jewelry making among others. Their utility across different industries has made them invaluable.

Environmental Benefits

Moreover, high silver welding strips are recyclable hence they can be considered eco-friendly products since they help reduce waste thereby supporting sustainable manufacturing practices through silver recovery.

Uniformity and Trustworthiness

Such materials when bought from China High Silver Welding Strip Manufacturers with good reputation exhibit consistent dependability thus having consistent quality and performance assurance for reliable operations. Goods from China are reputed for being critically controlled by their manufacturers so that every one batch maintains a certain height approved by its manufacturer.

Compatibility with Automation Processes

With this kind of automated process integration in place, we can enhance the production efficiency and uniformity through incorporating high-silver welding strip into our automatic arc welding procedures for large volume manufacturing purposes.

Cost-Effective Solution

Highly functional though cheap rings these days exist because most people are interested in purchasing durable items as well as producing strong joints at low cost using superior performing high silver welding strips unlike other consumables. In addition it will cut down on maintenance costs over time compared to other options available today.

Better Flowability

The presence of noble metal increases the liquidizing property thereby allowing liquefied metal to flow better within surfaces thereof and fill in between. Thus, it creates a more even and complete bond thereby avoiding weak spots within the joint.

Yes, using an appropriate flux is recommended when welding with high silver strips to clean the metal surfaces and promote the flow of the molten metal, ensuring a strong and reliable bond.

Position the strip at the joint area, apply flux, heat the joint evenly until the strip melts and flows into the joint, and then allow it to cool slowly.

Store them in a cool, dry place away from moisture and contaminants to prevent oxidation and maintain their quality.

Remove any residual flux and oxides using appropriate cleaning methods, such as soaking in a mild acid solution or using a wire brush.

Yes, they are versatile and can join both ferrous and non-ferrous metals.

They produce minimal oxidation during the welding process, reducing the need for extensive post-welding cleaning.

Ensure proper surface preparation, use the right flux, and apply even heat to achieve a strong and reliable bond.