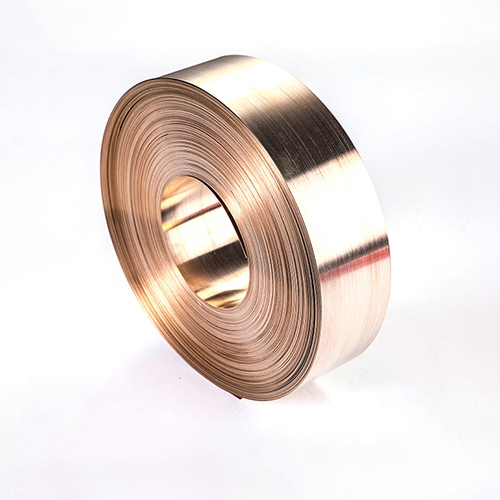

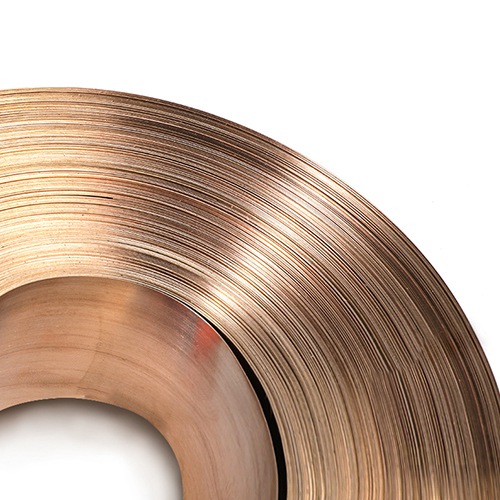

You can use High silver brazing alloy Solder to create joints with different qualities in many metalworking applications. The picture that comes with this text shows us a roll of solder that makes it easy to use and move. It has high silver content which leads to good conduction and strong bonding making it appropriate for both professional and hobbyist.

It is the best quality available from China Silver Solder Rod Suppliers because they are known suppliers of this high silver brazing alloy solder. The precise composition of the alloy facilitates smooth flowing, hence easier brazing. The ability of the alloy to flow properly while filling up gaps is the reason behind its uniform joint formation stress-free and resistant to corrosion.

It is versatile enough to be used in a number of applications including plumbing, HVAC systems, electrical connections, automotive repairs, jewelry etc. Besides creating durable bonds, having much silver enhances beautiful results with shiny finishing on what one gets.

Always opt for Chinese suppliers who stock high silver brazing alloy solders as they sell products meeting international standards when you need them. They always have their products tested before being shipped so that people will not buy things that are substandard anymore.

Ultimately, you cannot afford not High Silver Brazing Alloy Solder if you wish for good brazed joints in various purposes. This explains why those looking for perfection in their braising undertakings prefer it due its incomparable material characteristics that are defined by top Chinese manufacturers’ strict guidelines during production process.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Superlative Conductivity

One good thing to note about silver solder rods is that they possess very good conductivities both for electricity and heat, making them suitable for electronics, electrical engineering, and other areas where effective spread of heat and strong electrical connections are required.

Strong Attachment

The use of the silver solder rods in bonding results into very strong and durable joints that are fatigue resistant. Thus, even under harsh conditions the joined parts will be bonded safely over extended periods.

Resistivity to corrosion

Silver has high resistance to oxidation and corrosion; hence it is appropriate in manufacturing silver solder rods that would be used on final products that might come into contact with water or any other elements that corrode metals thereby enhancing durability.

Withstanding High Temperature

This makes them ideal for use in applications with high thermal loads since silver solder rods can bear high temperatures without distorting their integrity and stability thus keeping their joints intact even when subjected to extreme heating.

Flexibility

Moreover, silver solders are compatible with various base metals such as copper, brass, nickel, stainless steel etc., hence they can be used for many different purposes starting from jewelry production and ending up in mass industrialization.

Artistic Expression

Besides being useful material, these sticks have a delightful finish which jewelry makers value most highly. The visual appeal of the final product is boosted by the bright shiny look of silver metal.

Simplicity of Application

Simple application methods make using these sticks easy especially during accurate fixing which ensures neatness in every soldering job; therefore they are considered the best choice by most professional as well as amateur users who look out for reliability and simplicity in tools respectively.

Yes, they are commonly used to join copper and brass pipes and fittings in plumbing due to their strong bonding and corrosion resistance.

No, once melted and used, the rod cannot be reused. It is designed for single-use only.

Yes, their bright and shiny appearance makes them suitable for jewelry making and other decorative applications.

Yes, they are used for joining components in aircraft and spacecraft due to their strong and reliable bonding properties.

Can silver solder rods be used in HVAC systems?

Yes, they are commonly used in HVAC systems to join copper tubing and fittings, ensuring leak-proof and durable connections.