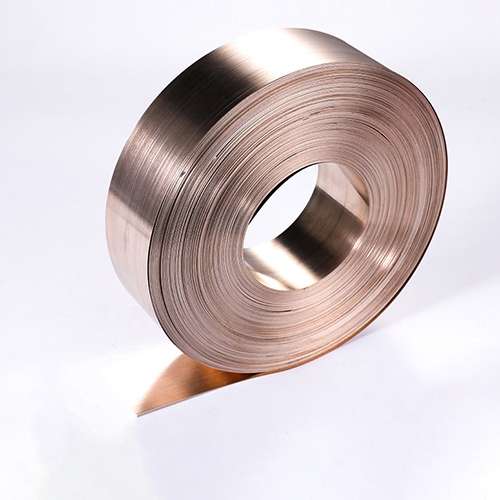

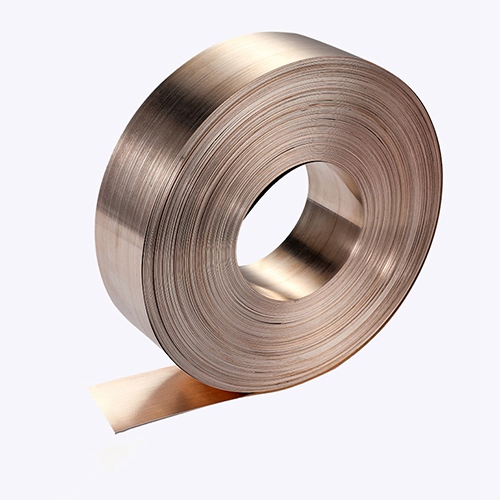

Silver Solder for Electronics is a high quality product made to construct robust, dependable links in electronics. This solder comes in a handy roll form as seen from the pictures that make it easy to handle and apply with accuracy. It has a high silver content, meaning it is highly conductive and bonds well thereby being suitable for intricate electronic works.

Supplied by top China high temp silver solder Suppliers, this silver solder stands out because of its excellent quality and performance. Composition of the alloy has been designed to give it a lower melting point that enables a more smooth and efficient process of soldering. In addition, it has an amazing ability to fill gaps by flowing smoothly into joints resulting into uniform bonds free from stress or corrosion.

Additionally, Silver Solder for Electronics can be used in various applications such as circuit board assembly, connector & terminal soldering, and repairing electronic devices. High silver content means strong and lasting joints as well as better general performance of electronic components through exceptional electrical conductivity which results in low electrical resistance.

When purchasing this item from good suppliers such as China High Temp Silver Solder Suppliers you are guaranteed that you will get the highest quality product with maximum output efficiency. The suppliers have quality assurance measures that are so strict ensuring consistency in each batch produced.

In conclusion, Silver Solder for Electronics is an important tool needed for achieving good soldered connections in different types of electric applications. With superior material properties and stringent manufacturing standards applied by the leading Chinese producers – a choice for those who seeks excellence through their electronical solders’ projects.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Exceptional Conductivity

High temp silver solder exhibits outstanding electrical and thermal conductivity thus making it ideal for heat efficient distribution such as strong electric connections like electronics, high precision instruments, especially in the electronic equipment.

Strong Bonding

The presence of high silver content in High temp silver solder makes it to have very strong and durable joints.It ensures that the bonded parts does not collapse even when subjected to heavy loads and stress.

Corrosion Resistance

Silver is highly anti-corrosive and can hardly rust under any circumstances making it suitable to be used as a high temp solder where there is likelihood of exposure to moisture, chemicals or other corrosive agents for durability purposes.

High-Temperature Performance

High temp silver solder is capable of withstanding extreme temperatures corresponding to those situations involving significant thermal loads; this condition stabilizes and maintains joint integrity even at high temperatures.

Versatility

High-temp silver solders are used with different base metals including copper, brass, nickel, stainless steel etc., which allows its application in an array of areas from electronic components to industrial manufacturing.

Ease of Use

It is easy to handle or apply High temp silver solder thereby providing clean and precise application preferred by both professional solderers and amateur hobbyists who require straightforward materials without complications or unnecessary frills.

Reduced Oxidation During Soldering

When using this type of material during the process oxidation level is quite insignificant hence minimal post-soldering cleaning required leading reduced aesthetic as well as structural damage for joints since they remain intact without extensive unnecessary cleaning after completing joining operation using these solders characterized by low oxidations levels during their use.

High temp silver solder can be used to join a variety of metals, including copper, brass, nickel, stainless steel, and other alloys.

Yes, using an appropriate flux is recommended when soldering with high temp silver solder to clean the metal surfaces and promote the flow of the molten metal, ensuring a strong and reliable bond.

The melting point typically ranges from 620°C (1148°F) to 800°C (1472°F), depending on the specific alloy composition.

Yes, they can withstand high temperatures, making them suitable for applications involving significant thermal loads.

Clean the surfaces thoroughly to remove dirt, grease, and oxides. Proper surface preparation ensures a strong and reliable bond.

Yes, it is commonly used to join copper and brass pipes and fittings in plumbing due to its strong bonding and corrosion resistance.