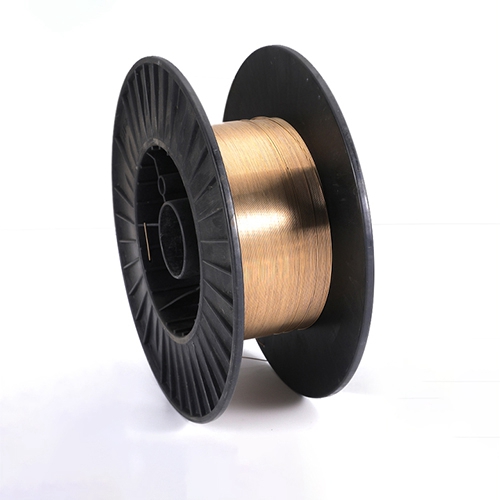

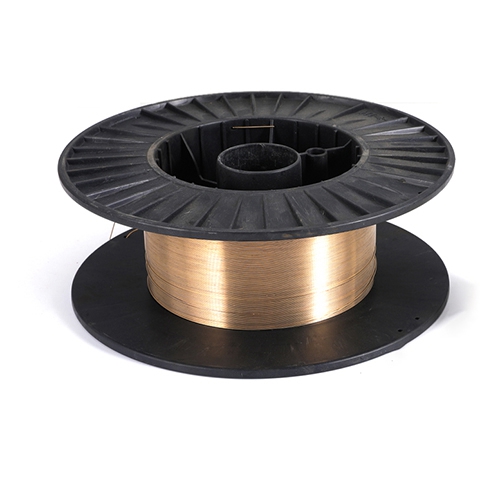

Guangdong Guangyanlong Welding Materials Co., Ltd, was founded in 2009 and is one of China’s best-known manufacturers of high-quality brazing materials. Each picture represents our topnotch Copper silver brazing wire which are prepared with utmost care to give good bonds even in such industrial applications as plumbing, refrigeration and electrical components. As the leading Chinese Copper silver brazing Wire Manufacturer, we can say that we never stop at anything and always go beyond technical boundaries ensuring that our products meet all international quality requirements including ISO9001:2015 and 16949 certifications.

Our silver brazing wire provides better flux characteristics, hard joint formation, and resistance to corrosion making it suitable for both ferrous and non-ferrous metals. This wire comes in different sizes depending on customer needs. In line with this, at Guangyanlong we strive to deliver eco-friendly energy efficient brazing solutions that not only reduce manufacturing costs but also enhance efficiency while improving product quality. Our extensive research and development ensures that our products remain industry leaders delivering reliable performance with a wide range of applications.

Therefore, by prioritizing customer satisfaction Guangyanlong has continued expanding its global reach through unrivaled brazing technology services available to clients worldwide.

●Cadmium-Free Silver-Based Solder

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

●Cadmium-Containing Silver-Based Solder

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Superb Jointing Strength: Copper Silver Brazing Wire gives extremely tough joints that ensure long-lasting connections between various metals such as copper, brass and steel. This is necessary in applications where high stress is considered vital for any entity that needs to be reliable.

Exemplary Resistance to Corrosion: The presence of copper and silver alloy in the wire makes it resistant to corrosion, hence can be used in areas where the joint may get exposed to moisture or chemicals.

Reduced Melting point: Copper silver brazing wire has a lower melting point than other brazing materials leading to faster and more effective brazing processes increasing thermal distortion on base metal including workpiece integrity.

High Electrical Conductivity: The electrical conductivity of this wire is enhanced by its content of silver, which makes it suitable for use in electrical and electronic applications that require strong, conductive joints.

Adaptability: Various industries such as HVAC, plumbing, electrical manufacturing among others find this brazing wire useful because it works with several types of metals including ferrous and non-ferrous ones.

Smooth Flow Characteristics: Copper Silver Brazing Wire flows smoothly during the process of brazing thereby resulting into uniformity and completeness of the area around the joint thus making a clean finish which will make it look professional after all.

Eco-Friendly: Guangdong Guangyanlong Welding Materials Co., Ltd strives to manufacture Copper Silver Brazing Wire that considers environmental issues. It does not contain any harmful substances such as lead hence it’s safe for both users and the environment.

Options for Personalization: A variety of sizes and compositions are available for our customers who want to have different designs made out of Copper Silver Brazing Wire. This helps in enhancing performance at an optimal cost.

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Copper Silver Brazing Wire is compatible with a wide range of metals, including copper, brass, bronze, steel, and stainless steel, making it versatile for various applications.

It offers superior bonding strength, excellent corrosion resistance, lower melting points, high electrical conductivity, and smooth flow characteristics, ensuring strong and reliable joints.

Common applications include joining pipes in plumbing, HVAC systems, refrigeration units, electrical connectors, and various components in automotive and aerospace industries.

The melting point typically ranges between 620°C to 800°C (1150°F to 1470°F), depending on the specific alloy composition.

Use appropriate protective gear, work in a well-ventilated area, and follow all safety guidelines provided by the manufacturer to avoid exposure to fumes and high temperatures.

Copper Silver Brazing Wire is available in various diameters, typically ranging from 0.5mm to 3.0mm, with custom sizes available upon request.

Our Copper Silver Brazing Wire is certified under ISO9001:2015 and 16949, ensuring it meets international quality standards.