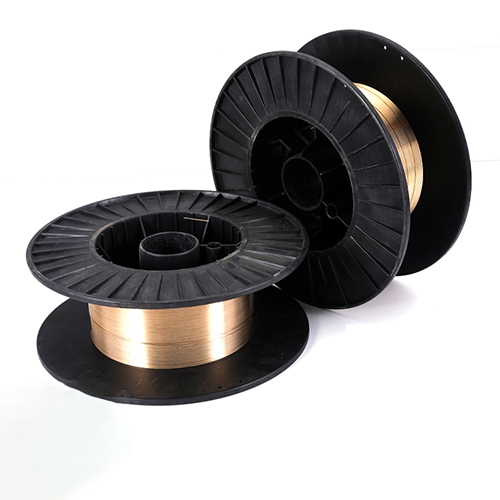

Guangdong Guangyanlong Welding Materials Co., Ltd, established in 2009, is a leading Chinese manufacturer specializing in the production of high-quality solders and brazing materials. The Silver Alloy Welding Wire shown in the pictures is one of our products that are suitable for use with electronics, plumbing and HVAC systems. As a Chinese soldering silver wire Manufacturer, we are always excited to take up technical challenges while offering environment-friendly solutions that are highly innovative yet energy efficient.

Our Soldering Silver Wires meet international standards such as ISO9001:2015 and 16949 certifications which guarantee their highest quality and reliability. It is available in different diameters for manual as well as automatic solder joints thus having strong corrosion resistant bonds. We at Guangyanlong always strive to enhance our production processes and management procedures; each order is meticulously handled with due care and precision. Our dedication to delivering quality service aimed at satisfying our customers’ needs has enabled us become a reliable partner among many industries worldwide who offer unique soldering solutions for improving productivity of manufactures and durability of products.

●Cadmium-Free Silver-Based Solder

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||

| Ag | Cu | Zn | Sn | F | ℃ | F | ℃ | |||

| BAg5CuZn | 5 | 58 | 37 | / | 1545 | 840 | 1615 | 880 | Suitable for nickel-chromium alloy resistance components, brazing and heat treatment can be performed at the same time. Suitable for copper-based alloys such as brazing/cyanide hardening by changing instruments or joining steel parts. Suitable for steel, brazing and heat treatment at the same time. Low silver solder for ferrous and non-ferrous metals. | |

| BAg7CuSn | 7 | 85 | / | 8 | 1225 | 665 | 1805 | 985 | ||

| BAg10CuZn | 10 | 83 | 37 | / | 1499 | 815 | 1562 | 850 | ||

| BAg15CuZnSn | 15 | 47 | 37 | 1 | 1364 | 740 | 1526 | 850 | ||

| BAg18CuZnSn | 18 | 47.5 | 33 | 1.5 | 1436 | 780 | 1490 | 830 | ||

| BAg20CuZn | 20 | 45 | 35 | / | 1319 | 715 | 1499 | 815 | ||

| BAg25CuZn | 25 | 41 | 32 | / | 1292 | 700 | 1472 | 800 | ||

| BAg35CuZn | BAg-35 | 35 | 32 | 33 | / | 1265 | 685 | 1390 | 754 | |

| BAg38CuZnSn | 38 | 32 | 28 | 2 | 1200 | 650 | 1330 | 720 | ||

| BAg40CuZn | 40 | 30 | 30 | / | 1245 | 675 | 1340 | 725 | ||

| BAg40CuZnSne | BAg-28 | 40 | 30 | 28 | 2 | 1200 | 650 | 1310 | 710 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1225 | 665 | 1370 | 745 | |

| BAg45CuZnSn | 45 | 27 | 25 | 3 | 1185 | 640 | 1260 | 680 | ||

| BAg50CuZnSn | 50 | 20 | 28 | 2 | 1220 | 660 | 1305 | 705 | ||

| BAg56CuZnSn | BAg-13a | 56 | 42 | / | 2 | 1420 | 770 | 1640 | 895 | |

| BAg60CuZn | 60 | 25 | 15 | / | 1245 | 675 | 1325 | 720 | ||

| BAg25CuZnSn | BAg-37 | 25 | 40 | 33 | 2 | 1270 | 690 | 1435 | 780 | It has lower melting point, high strength, good brazing process and good overall joint performance. It can braze copper and copper alloys, steel and stainless steel as well as quenched and tempered steel with lower brazing temperature. |

| BAg30CuZnSn | 30 | 36 | 25 | 2 | 1202 | 650 | 1346 | 750 | ||

| BAg34CuZnSn | 34 | 36.5 | 27 | 2.5 | 1166 | 630 | 1346 | 730 | ||

| BAg40CuZnSn | BAg-28 | 40 | 30 | 28 | 2 | 1173 | 634 | 1364 | 740 | |

| BAg45CuZn | BAg-5 | 45 | 30 | 25 | / | 1229 | 665 | 1373 | 745 | |

| BAg45CuZnSn | BAg-36 | 45 | 27 | 25 | 3 | 1184 | 640 | 1256 | 680 | |

| BAg50CuZn | 50 | 25 | 25 | / | 1274 | 690 | 1427 | 775 | ||

| BAg50Cu | BVAg-6b | 50 | 50 | / | / | 1435 | 780 | 1600 | 870 | |

| BAg56CuZnSn | BVAg-7 | 56 | 23 | 16 | 5 | 1144 | 618 | 1205 | 652 | |

| BAg72Cu | BVAg-8 | 72 | 28 | / | / | 1434 | 779 | 1434 | 779 | |

●Cadmium-Containing Silver-Based Solder

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | ||||||

| Ag | Cu | Zn | Cd | Ni | F | ℃ | F | ℃ | |||

| BAg18CuZnCd | 18 | 39 | 28 | 15 | / | 1184 | 640 | 1373 | 745 | Used for low-cost brazing of copper and copper alloys, steel and stainless steel. | |

| BAg20CuZnCd | 20 | 40 | 25 | 15 | / | 1121 | 605 | 1409 | 765 | ||

| BAg25CuZnCd | BAg-33 | 25 | 30 | 27.5 | 17.5 | / | 1124 | 607 | 1259 | 682 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BAg30CuZnCd | BAg-2a | 40 | 28 | 21 | 21 | / | 1112 | 600 | 1274 | 690 | |

| BAg35CuZnCd | BAg-2 | 45 | 26 | 21 | 18 | / | 1121 | 605 | 1292 | 700 | |

| BAg40CuZnCd | 45 | 16.8 | 17.5 | 25.5 | 0.2 | 1103 | 595 | 1121 | 605 | ||

| BAg45CuZnCd | BAg-1 | 50 | 15 | 16 | 24 | / | 1124 | 607 | 1146 | 619 | |

| BAg50CuZnCd | BAg-3 | 50 | 16.5 | 14.5 | 16 | 3 | 1169 | 632 | 1270 | 688 | |

Electrically conductive: Soldering Silver Wire is highly electrically conductive, making it suitable for use in electronics that require dependable and effective connections.

Stronger Joints: The silver wire has high mechanical stress resistance resulting in strong joints hence is ideal for applications with high stresses in different industries.

Resistance to corrosion: Because of its natural corrosion resistant character, the Soldering Silver Wire joins are not only long-lasting but also reliable during harsh environmental conditions.

Low Melting Point: In soldering silver wires normally have a lower melting point than other solders which aids in fastening processes and reduces chances of heat damage on delicate parts.

Smooth Flow Characteristics: This product ensures an even spread over the joint and this stick unlike most products where they look like they were done by an amateur.

Brass solder has a wide range of applications and is commonly used in ordinary flame welding. It is mainly used in refrigeration, air conditioning, plumbing and electrical industries. We can produce all kinds of formulas, and can also cooperate with R&D and customization to reduce costs and increase efficiency for your production. Specifically Please contact the technical department if required.

Soldering Silver Wire offers higher strength, better conductivity, and superior corrosion resistance compared to traditional tin-lead solder, making it a more durable and reliable option.

Store the wire in a cool, dry place away from moisture and contaminants. It is best to keep it in its original packaging until use to prevent oxidation.

Soldering Silver Wire performs well in high-temperature environments due to its thermal stability, making it suitable for applications that require heat resistance.

We adhere to strict manufacturing standards and conduct rigorous quality control tests to ensure our Soldering Silver Wire meets international standards such as ISO9001:2015 and 16949 certifications.

By being lead-free and manufactured with environmentally friendly processes, Soldering Silver Wire contributes to reducing environmental impact and promoting sustainability.